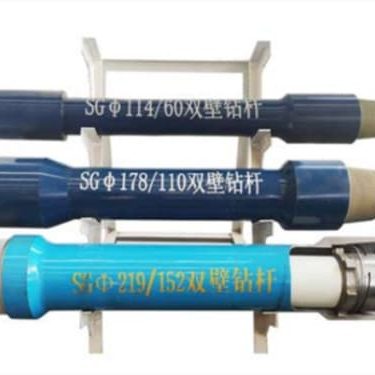

Slotted Liners/Pipes

- Materials: API 5CT j55/k55/N80, stainless steel ASTM304, 316 and 316L

- Size: 2 3/8”- 20”(60.3mm-508mm)

- Thickness: Less than 16mm

- Slot shape: Slotted or custom

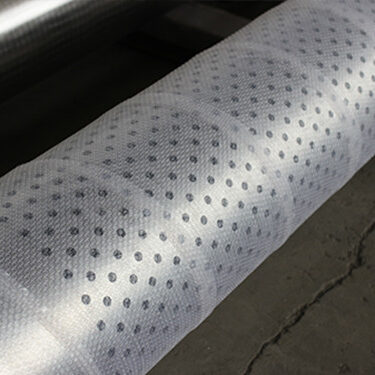

- Slot style: Straight slot, single slotted staggered/nonstaggered rows, keystone slot

Slotted Liners/Pipes

Slotted liners or pipes are used in oil and gas wells to prevent sand and other debris from entering the production zone. They also act as a separator to filter out sand and other contaminants from the oil. Slots are formed through the casing or tube, a process called “perforation.” They can be circular, asymmetrical, or even oval in shape. Narrow straight-cut slots are more effective at keeping out dirt and other debris than circular holes, which can clog the pipe. The most common type of perforated pipe is keystone shaped, with narrower openings on the outside surface of the casing or tube than the inside. The narrower openings allow sand grains to bridge across the outside rather than wedge into the pipe. This reduces the likelihood of a plugging event, and improves the effectiveness of sand control in your well. Straight-cut slots are typically used in almost horizontal completions such as steam assisted gravity drainage (SAGD). They’re a cost-effective alternative to the keystone or under-cut slot, and are often recommended for wells with a relatively low productivity factor. They’re also a good choice for wells that require high levels of sand control. The straight-cut slotted pipe can be made by carbon steel, stainless steel and alloy steel. Stainless steel or alloy steel is more durable than carbon steel and offer greater resistance to corrosion and wear.

Wiho industrial is a quality manufacturer and supplier in China that can offer you a wide variety of API prime OCTG Tubing and Casing for sand control during the process of oil production. We offer a range of straight or keystone-shaped slots casing pipes used where well productivity is small and economics can not support the use of the screen. Our slotted casings are produced by laser cutting which offers higher dimensional accuracy and makes the cuts a smooth surface and faster production.

Features of Slotted Liners/Pipes

Less prone to clogging and pressure drops

Less expensive than screens

laser cutting is easier and faster and higher dimensional accuracy

Low comprehensive cost and long lifespan.

Specifications of Slotted Liners/Pipes

|

API Std Casing |

ID mm |

Length

m |

Slot Length

mm |

Slot

No. /m |

Slot width

mm |

Slot Tolerance |

Valid Filter Area cm/m |

||

| Spec

mm |

Thickness

mm |

Per Weight

kg/m |

|||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 |

| 73.02 | 5.5 | 9.15 | 62 | 3 | 80 | 240 | 57.6 | ||

| 88.9 | 6.5 | 13.22 | 75.9 | 3 | 80 | 280 | 67.2 | ||

| 101.6 | 6.5 | 15.22 | 88.6 | 3 | 80 | 300 | 72 | ||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 80 | 320 | 76.8 | ||

| 127 | 7.52 | 22.13 | 112 | 10 | 80 | 340 | 81.6 | ||

| 139.7 | 7.72 | 25.11 | 124.3 | 10 | 80 | 360 | 86.4 | ||

| 9.17 | 29.48 | 121.4 | 10 | 80 | 360 | 86.4 | |||

| 168.3 | 8.94 | 35.09 | 150.4 | 10 | 80 | 400 | 96 | ||

| 177.8 | 8.05 | 33.68 | 161.7 | 10 | 80 | 440 | 105.6 | ||

| 9.19 | 38.19 | 159.4 | 10 | 80 | 440 | 105.6 | |||

For more information on our extensive size and inventory, please contact us or fill in the form below.