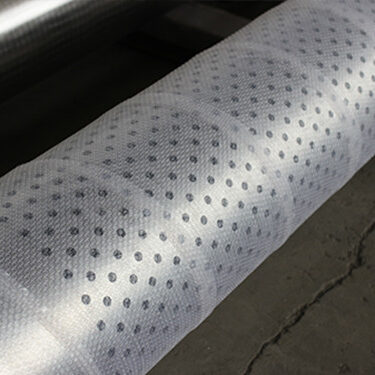

Pipe Base Well Screen

- Material: Stainless and Carbon steel

- Size: 3-1/2” through 9-5/8” O.D.

- Wire width: 0.090”

- Thicker gravel packs (3/8” to 5/8”) are available if extra sand retention properties are needed.

Pipe Base Well Screen For Oil and Gas

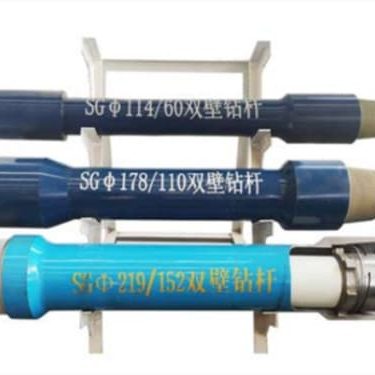

A pipe base screen, also known as a double-layer screen, is a kind of sand control screen that combines the hydraulic efficiency of a continuous slot wedge wire screen with the strength of a pipe. This screen is a new generation of well screen that has been developed in recent years. It consists of a sand control screen, a perforated pipe, a slotted casing and a stainless steel or carbon steel wire mesh base. This screen is designed for sand control and water filtration and is particularly suited for both vertical and horizontal boreholes. It is a high-efficiency sand control and water filtration screen for both shallow and deep wells, vertical and horizontal boreholes or sand control and water filtration in bore wells. It is a good substitute of the traditional sand control screen for wells with sandy soils or a muddy bottom. Its main functions include: sand retention, formation sand removal and production retaining, can be used in oil or gas well drilling in many countries. This sand screen is using stainless steel base pipe or API 5CT carbon steel casing inside and wire screen jacket to enhance the capacities and high tensile strength loads for deep wells. Its strength is superior to that of a single-layer screen, thus it can be more reliable than a single-layer screen. It’s unique construction and can be used in open hole, standalone or gravel-pack wells, which provides excellent service for oil or gas well drilling.

Wiho industrial is a quality manufacturer in China that can offer you a wide variety of API prime OCTG Tubing and Casing for oil production activities onshore and offshore. We offer a range of well screening solutions to help you maximize production from unconsolidated formations while enhancing wellbore stability. We have experience in developing, manufacturing and deploying a wide range of screening technologies including wire-mesh screens, slip-on wire jackets, wrap-on-pipe screens, and screen inflow control technology that fits your needs and budget.

Features of Pipe Base Well Screen

High flow rate and low frictional head loss.

Easy backwashing and long lifespan.

Self-cleaning action, no clogging and reduced flow friction.

Low comprehensive cost and long lifespan.

Specifications of Pipe Base Well Screen

|

Base pipe |

Screen jackets |

||||||||

|

Nominal Diameter |

O.D | Weight(lb/ft)

W.T(mm) |

Hole diameter(in) | Hole Area

(in2/ft) |

Screen jacket

OD(in) |

Open Area(In2/ft) Slot(in) |

|||

| 0.008’’ | 0.012 | 0.015 | 0.02 | ||||||

| 2-3/8 | 60 | 4.6(4.83) | 3/8 | 10.6 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

| 2-7/8 | 73 | 6.4(5.51) | 3/8 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

| 3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

| 4 | 101.6 | 9.5(5.74) | 1/2 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

| 4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

| 5 | 127 | 13(6.43) | 1/2 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

| 5-1/2 | 139.7 | 15.5(699) | 1/2 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

| 6-5/8 | 168.3 | 24(8.94) | 1/2 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

| 7 | 177.8 | 23(8.05) | 5/8 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

| 7-5/8 | 194 | 26.4(833) | 5/8 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

| 8-5/8 | 219 | 2(8.94 | 5/8 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

| 9-5/8 | 244.5 | 36(8.94) | 5/8 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

| 10-3/4 | 273 | 45.5(10.16) | 5/8 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

| 13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

For more information on our extensive size and inventory, please contact us or fill in the form below.