What’s Deep Hole Drilling?

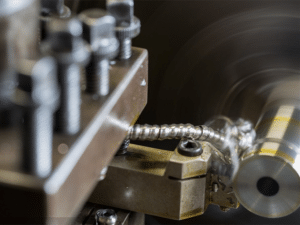

Deep hole drilling, compared with conventional drilling processes, is the drilling process with a high length-to-diameter ratio of boreholes, usually greater than 10:1. The process can achieve high drilling quality with low surface roughness and small diameter deviations. It also has high productivity and low burr formation, making them economical even at low drilling depths. They’re commonly used deep hole drilling methods include: gundrilling, BTA drilling, ejector drilling.

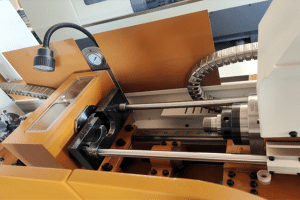

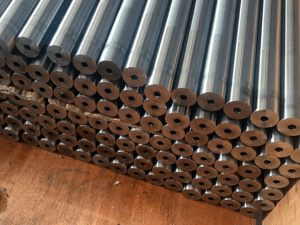

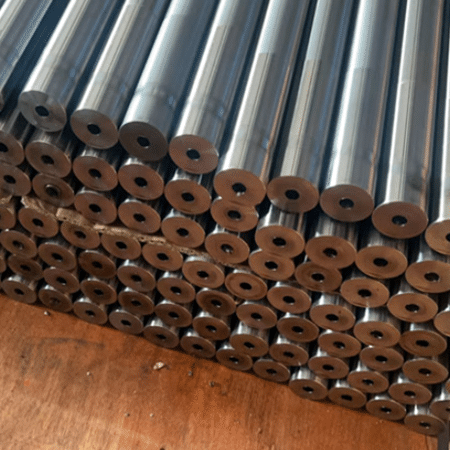

At WIHO industry, we mainly process deep hole drilling and boring by using gun drilling. The materials we process include steel alloys, copper alloys, aluminum alloys, titanium alloys, etc., with the bar size 7mm-100mm O.D and Hole size1.0-35mm O.D and 50-1000mm depth. The deep hole drilling workpiece is used where high-precision holes are required for components like aerospace, automotive, medical, and energy industries.Typical applications include Hydraulic cylinders, engine parts, fuel injectors, heat exchanger tubes, aircraft landing gear, implants, and solar panels.