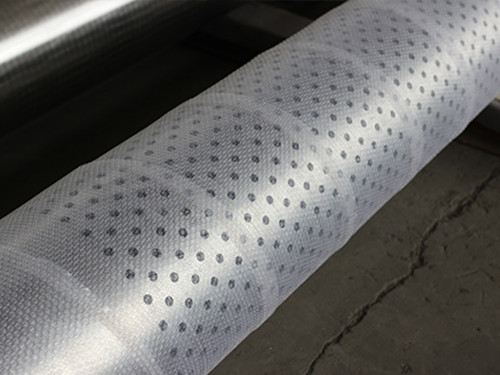

Perforated Casing Screen Pipes

- Materials of Base Tube: API J55/K55, N80,13CR110 Casing pipe

- OD: 2 3/8″ – 7″

- Length: R2, R3

- Connection: API and Premium Connection

Perforated Casing Screen Pipes

Perforated casing screen pipes are an essential component in the oil and gas industry. These pipes are designed to allow fluid to flow through the small holes or slots in the pipe’s walls while keeping the soil and other particles out. It’s the perfect solution for aquifer protection, filtering sediment from water sources, controlling fluid levels during well construction, or providing drainage pathways. With their sturdy construction and reliable performance, perforated casing screen pipes have become the go-to choice for many industries around the world. This feature makes them ideal for use in a wide variety of applications, including water wells, geothermal systems, and gas wells. These pipes are typically made of materials such as stainless steel or carbon steel which can be lined and coated as needed which can withstand the harsh conditions of the drilling environment. This type of pipe is available in a variety of sizes and shapes, including round, square, and rectangular. It can be welded, bolted, or clamped to another pipe.

Wiho industrial is a quality manufacturer in China that can offer you a wide variety of API prime OCTG Tubing and Casing for sand control during the process of oil production. We offer a range of perforated screening solutions for well stimulation, horizontal wells and offshore wells, etc. The perforated liner or pre-perforated casing is manufactured with a 44ft 88 spindle drill press and the joints with sizes up to 20” are perforated in one handling. We have experience in developing, manufacturing and deploying a wide range of screening technologies including wire-mesh screens, slip-on wire jackets, wrap-on-pipe screens, and screen inflow control technology that fits your needs and budget.

Features of Perforated casing screen pipes

API casing or tubing base-pipe.

High flow rate and low frictional head loss.

Easy backwashing and long lifespan.

Self-cleaning action, no clogging and reduced flow friction.

Low comprehensive cost and long lifespan.

Specifications of Perforated casing screen pipes

|

Pipe Size (inch) |

Hoses per feet (sq in./ft) | Hole size (inch) | Open Area per feet (sq in./ft) |

|

3/4 |

78 | 3/16 |

2.15 |

|

1 |

54 | 5/16 |

4.14 |

|

1-1/4 |

66 | 5/16 |

5.06 |

|

1-1/2 |

78 | 5/16 | 5.98 |

|

2-1/16 |

78 | 5/16 |

5.98 |

| 2-3/8 | 90 | 3/8 |

9.94 |

|

2-7/8 |

102 | 3/8 | 11.26 |

|

3-1/2 |

126 | 3/8 |

13.91 |

|

4 |

138 | 3/8 | 15.24 |

| 4-1/2 | 150 | 3/8 |

16.56 |

| 5 | 162 | 3/8 |

17.88 |

|

5-1/2 |

174 | 3/8 | 19.21 |

| 6-5/8 | 186 | 3/8 |

20.53 |

|

7 |

222 | 3/8 | 24.51 |

| 9-5/8 | 294 | 3/8 |

32.46 |

For more information on our extensive size and inventory, please contact us or fill in the form below.