API 5CT L80-1/9Cr/13Cr Casing Pipe

Steel Mill: TPCO, BAO STEEL, VALIN STEEL

Steel Grade/Material: L80

Outer Diameter(OD): 4 1/2”-20”(114.3mm-508mm)

Wall Thickness(WT) : 9.5LB/ft-133LB/ft(5.21mm-16.13mm)

Length: R1/R2/R3

Threads: Nonupset threaded end(NUE), External upset threaded end(EUE)

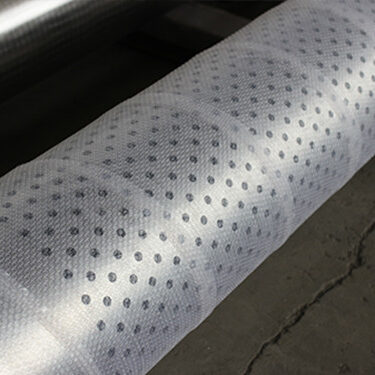

According to American Petroleum Institute Standard API SPEC 5CT, a specification for casing and tubing for petroleum and natural gas industries-used for wells, the steel oil casing pipe can be divided into ten types: H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 and Q-125. Grade L80 casing tubing is an API 5CT oil casing pipe and is mostly used for oil well under sour (H2S) environments with varied end connections such as non-upset ends or an external upset end. L80 family includes L80-1, L80-9Cr, and L80-13Cr, is a group of pipe for corrosion-resistant casing application. Wiho metals is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT L80 type 1, type 9Cr, and type 13Cr as well as their casing coupling, perforated pipe and more. Contact us for more details with the form below.

What’s the difference between API 5CT L80-1, L80-9Cr and L80-13Cr?

API 5CT L80 type 1, type 9Cr and type 13Cr have the same mechanical properties and delivery condition, the difference lies in the term of use, production difficulty and price.

- Uses: L80-1 is used in the H2S condition, while L80-9Cr and L80-13Cr are used for the CO2 environment such as heavily corroded well, are the casing tubing with high corrosion resistance. In the corrosive environment in which carbon dioxide predominates, Super 13Cr has a higher corrosion resistance than L80-13Cr.

- Price: L80-1 is general oil tubing, with relatively high price, the L80- 9Cr and L80-13Cr apply to more complicated geological conditions and runs down deeper into the well.

- API color code (bands): 1 red + 1 brown (L80), 1 red + 1 brown + 2 yellow (L80 9Cr), 1 red + 1 brown + 1 yellow (L80 13Cr)

API 5CT L80 Chemical Composition

| Grade | Type | C | Mn | Mo | Cr | Ni max. | Cu max. | P max. | S max. | Si max. | ||||

| min. | max. | min. | max. | min. | max. | min. | max. | |||||||

| L80 | 1 | – | 0.43 a | – | 1.9 | – | – | – | – | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 |

| L80 | 9Cr | – | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8.0 | 10.0 | 0.5 | 0.25 | 0.02 | 0.01 | 1.00 |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1.00 | – | – | 12.0 | 14.0 | 0.5 | 0.25 | 0.02 | 0.01 | 1.00 |

API 5CT L80 Mechanical Property

| Grades | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation under load, % | Hardness, HRC |

| L80-1/L80-9Cr/13C | 552-655 | 655 | 0.5 | 23 |

API 5CT Production Tubing Size

| Nominal dimension(in) | O.D(No thickened) mm | I.D(No thickened)

(mm) |

O.D(Thickened)

mm |

I.D(Thickened)

mm |

Coupling O.D(No thickened)

mm |

Coupling O.D

thickened) mm |

| 1 1/2 | 48.3 | 40.3 | 53.2 | 40.3 | 55 | 63.5 |

| 2 3/8 | 60.3 | 50.3 | 65.9 | 50.3 | 73 | 78 |

| 2 7/8 | 73.0 | 62.0 | 78.6 | 62.0 | 89.5 | 93 |

| 3 1/2 | 88.9 | 75.9 | 95.25 | 75.9 | 107 | 114.5 |

| 4 | 101.6 | 88.6 | 107.95 | 88.6 | 121 | 127 |

| 4 1/2 | 114.3 | 100.3 | 120.65 | 100.3 | 132.5 | 141.5 |

API 5CT Production Casing Size

| O.D mm(in) | Coupling O.D

(mm) |

I.D

(mm) |

Size (mm) | O.D mm(in) | Coupling O.D

(mm) |

I.D

(mm) |

Size (mm) |

| 114.3

(4 1/2) |

127.0 | 103.9 | 100.7 | 177.8

(7) |

194.5 | 166.1 | 162.9 |

| 102.9 | 99.7 | 164.0 | 160.8 | ||||

| 101.6 | 98.4 | 161.7 | 158.5 | ||||

| 99.6 | 96.4 | 159.4 | 156.2 | ||||

| 127

(5) |

141.3 | 115.8 | 112.6 | 193.7

(7 5/8) |

215.9 | 178.5 | 175.3 |

| 114.1 | 111.0 | 177.0 | 173.8 | ||||

| 112.0 | 108.8 | 174.6 | 171.5 | ||||

| 108.6 | 105.4 | 171.8 | 168.7 | ||||

| 139.7

(5 1/2) |

153.7 | 127.3 | 124.1 | 219.1

(8 5/8) |

244.5 | 205.7 | 202.5 |

| 125.7 | 122.6 | 203.7 | 200.5 | ||||

| 124.3 | 121.1 | 201.2 | 198.0 | ||||

| 121.4 | 118.2 | 198.8 | 195.6 |