API 11B Sucker Rods

Steel Mill: MoLong Steel

Standards: API Spec 11B

OD: 5/8″, 3/4″, 7/8″, 1″, 1 1/8″

Grades:C, K, D, high strength,anti-corrosive coating, polished

Rod lengths: 7.72m, 8.00m, 9.14m(Normal )

The sucker rod is a crucial component of rod pumping equipment. It connects the upper rod to the pumping unit through a coupling. The plunger of the pumping unit is attached to the sucker and the sucker is set to transfer the movement of the ground pumping unit to the downhole oil pump. API 11B classifies common steel sucker rods into four grades: C, D, K and H. Common sucker rod has the advantages of simple production, low cost, small diameter, and wide application range, and its utilization rate accounts for more than 90% of sucker rod pumping Wells.

Wiho Metals supplies and stocks a large inventory of Steel Sucker Rod and Pony Rod as per API Spec 11B, the standard API 11B for sucker rod defines the specifications of general sucker rod, fiber-strengthen plastic sucker rod, coupling, polished and special sucker rods for size, mechanical properties, inspection and test methods. Wiho metals cover the steel sucker rods products in Grade C, K, D, KD, HL, HY, available material available in carbon and alloy steel such as AISI 4130M, AISI 4138M, AISI 4320M, AISI 4330M, AISI 4142M, AISI 4621M, AISI 8630.

General API 11B Sucker Rods Grade

| Grade | Yield strength, min | Tensile strength, min | Material | Reduction of area | Applications |

| Grade C | 415 MPa | 620-795 MPa | 4130M | ≥60 | For shallow Wells, light load conditions. |

| Grade K | 415 MPa | 620-795 MPa | 4130M,4320M,4320M,

4330M |

≥50 | For corrosive light/medium load Wells. |

| Grade D | 590 MPa | 795-965 MPa | 4621M | ≥50 | For medium and heavy-duty Wells. |

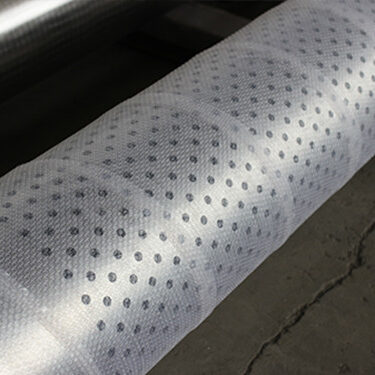

Corrosion of sucker rods is one of the biggest challenges facing oil production today. Our products also are supplied by high-grade alloy steel or treated with a thick protective layer through a special electroplating and polishing process, that provides effective corrosion resistance and high strength and extends the service life of any sucker rod to nearly double what it was before. The steel sucker rod with the polished process and the Nickel base alloy and Nano coating surface offer good wear-resistant and anti-corrosive coating, which enhances the pressure seal of the stuffing box and extends the working life of the steel rod.

High strength Sucker Rods Specifications

| Grades | Yield strength, min | Tensile strength, min | Hardness,HRC | Reduction of area | Elongation |

| HL | 795 MPa | 965-1195 MPa | / | ≥45 | ≥10 |

| HY | / | 42 | / | / | |

| N97 | 795MPa | 965-1034 MPa | / | ≥45 | ≥10 |

Polished Sucker Rods Specifications

| Types | Size | Grades | Length, m |

| Heavy | 1

1 1/8 1 1/4 1 1/2 |

H

D |

6.00

8.00 9.5 10.00 or custermorized |

| Normal |

High Strength Anti-corrosive Sucker Rods Specifications

| Types | Grades | Yield strength, min | Tensile strength, min | Reduction of area | Elongation | Length | Size |

| High strength | KD | ≥590 | 795-965 | ≥50 | ≥10 | 7.62m

8.00m 9.14m |

5/8

3/4 7/8 1 1 1/8 1 1/4 |

| NF75 | ≥689 | 862-965 | ≥45 | ≥10 | |||

| NF97 | ≥895 | 965-1195 | ≥45 | ≥10 | |||

| Anti-corrosive Coating | D/H | Surface coated with Nickel base alloy, nano anti-corrosive coating | |||||

For more information on our extensive steel alloys inventory, please contact us or fill in the form below.