What’s the plastic mold steel used for?

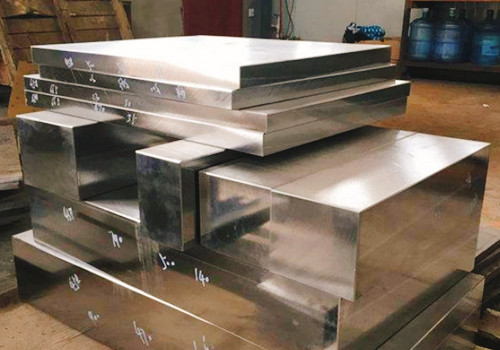

Mold steels can be divided into cold work mold steels, hot work mold steels and plastic mold steels. Plastic mold steel has accounted for more than 50% of the consumption of mold steel, has been used for the manufacture of plastic mold materials with different requirements. Therefore, many countries have formed their own codes of…