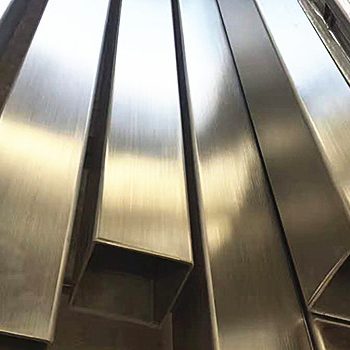

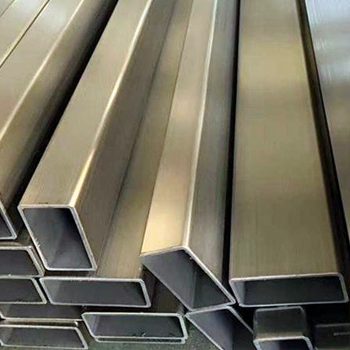

SAE J525 Hydraulic Steel Tubing

Diameter (OD) : 0.250” to 2.000”

Wall Thickness : 0.028” to 0.120”

Steel Grades:1006-1018

Heat Treatments: Cold Drawn , Full Annealing

Process: Welded

SAE J525 Standard covers normalized electric-resistance welded, cold-drawn, single-wall, low-carbon steel pressure tubing intended for use as pressure lines and in other applications requiring tubing of a quality suitable for bending, flaring, forming, and brazing. Wiho metals supply and stock a large inventory of SAE J525 welded tubing for hydraulic applications and in other applications requiring tubing of a quality suitable for flaring and bending. In addition, all of our tubes have an exceptionally bright and clean OD and ID, they ship with ends capped to prevent the entry of contaminants and ensure cleanliness.

SAE J525 Tubing Equivalent Specifications

ASTM /ASME A214 (Except for Average Wall)

AISI 1008/1010

Chemical Composition

| Carbon | 0.06-0.18 |

| Manganese | 0.30-0.6 |

| Phosphorus | 0.04max |

| Sulfur | 0.05 |

Mechanical Property

| Yield Strength, min | 170 MPa |

| Ultimate Strength, min | 310 MPa |

| Elongation in 50 mm, min | 35% |

| Hardness (Rockwell B), max | 65 |

SAE J525 Welded Tubing Tolerance

| Nominal Tubing OD | Tube Tolerance, OD±mm/ID±mm |

| Up to 9.50 | 0.05 |

| Over 9.50 to 15.88 inclusive | 0.06 |

| Over 15.88 to 50.80 inclusive | 0.08 |

| Over 50.80 to 63.50 inclusive | 0.10 |

| Over 63.50 to 76.20 inclusive | 0.13 |

| Over 76.20 to 100.00 inclusive | 0.15 |

SAE J525 Welded Tubing Pressure Rating

| Nominal Tube O.D. inch mm |

Nominal Tube Wall Thickness | ||||||||||||

| 0.028 | 0.035 | 0.049 | 0.065 | 0.083 | 0.093 | 0.109 | 0.12 | 0.134 | 0.148 | 0.156 | 0.188 | ||

| 0.71mm | 0.89mm | 1.24mm | 1.65mm | 2.11mm | 2.41mm | 2.77mm | 3.05mm | 3.40mm | 3.76mm | 3.96mm | 4.78mm | ||

| Reference Working Pressures at 4:1 Design Factor(psi/Mpa) | |||||||||||||

| 0.125 | 6650 | 8450 | |||||||||||

| 3.18 | 46 | 58.5 | |||||||||||

| 0.188 | 4250 | 5450 | |||||||||||

| 4.77 | 29.5 | 37.5 | |||||||||||

| 0.25 | 3100 | 3950 | 5750 | 7800 | |||||||||

| 6.35 | 21.5 | 27 | 39.5 | 54 | |||||||||

| 0.312 | 2450 | 3100 | 4500 | 6150 | |||||||||

| 7.92 | 16.8 | 21.5 | 31 | 42.5 | |||||||||

| 0.375 | 2000 | 2550 | 3650 | 5000 | 6550 | 7600 | |||||||

| 9.53 | 13.8 | 17.6 | 25 | 34.5 | 45 | 52.5 | |||||||

| 0.5 | 1850 | 2700 | 3650 | 4800 | 5550 | 6450 | 7200 | ||||||

| 12.7 | 12.8 | 18.6 | 25 | 33 | 38.5 | 44.5 | 49.5 | ||||||

| 0.625 | 1500 | 2100 | 2850 | 3750 | 4350 | 5050 | 5600 | ||||||

| 15.88 | 10.4 | 14.5 | 19.6 | 26 | 30 | 35 | 38.5 | ||||||

| 0.75 | 1200 | 1750 | 2350 | 3050 | 3550 | 4150 | 4600 | ||||||

| 19.05 | 8.3 | 12 | 16.2 | 21 | 24.5 | 28.5 | 31.5 | ||||||

| 0.875 | 1050 | 1500 | 2000 | 2600 | 3000 | 3500 | 3900 | ||||||

| 22.23 | 7.2 | 10.4 | 13.8 | 18 | 20.5 | 24 | 27 | ||||||

| 1 | 900 | 1300 | 1750 | 2250 | 2600 | 3000 | 3350 | 3800 | 4200 | ||||

| 25.4 | 6.2 | 9 | 12 | 15.5 | 18 | 20.5 | 23 | 26 | 29 | ||||

| 1.125 | 1150 | 1550 | 2000 | 2300 | 2650 | 2950 | 3300 | 3700 | |||||

| 28.58 | 7.9 | 10.6 | 13.8 | 15.8 | 18.2 | 20.5 | 23 | 25.5 | |||||

| 1.25 | 1000 | 1350 | 1750 | 2050 | 2350 | 2650 | 2950 | 3300 | 3500 | 4300 | |||

| 31.75 | 6.9 | 9.3 | 12 | 14.2 | 16.2 | 18.2 | 20.5 | 23 | 24 | 29.5 | |||

| 1.5 | 1150 | 1450 | 1700 | 1950 | 2150 | 2450 | 2700 | 2850 | 3500 | ||||

| 38.1 | 7.9 | 10 | 11.8 | 13.5 | 14.8 | 16.8 | 18.6 | 19.6 | 24 | ||||

| 1.75 | 950 | 1250 | 1450 | 1650 | 1850 | 2050 | 2300 | 2400 | 2950 | ||||

| 44.45 | 6.6 | 8.6 | 10 | 11.4 | 12.8 | 14.2 | 15.8 | 16.6 | 20.5 | ||||

| 2 | 850 | 1100 | 1250 | 1450 | 1600 | 1800 | 2000 | 2100 | 2550 | ||||

| 50.8 | 5.9 | 7.6 | 8.6 | 10 | 11 | 12.4 | 13.8 | 14.5 | 17.6 | ||||

Wiho Steel is a fully stocked and leading low carbon steel manufacturer, supplier, exporter, distributor of steel pipe, tubing. We supply and stock a large inventory of precious 1008, 1018 welded tubing in accordance with SAE J525 used for hydraulic parts. For more information on our extensive steel alloys inventory, please contact us or fill in the form below.