The cutting and grinding performance of most stainless steel is not good, it is difficult to process stainless steel parts with a smooth surface on high-speed automatic machine tools, the addition of sulfur, selenium, or lead and other elements can greatly improve the cutting (grinding) performance, free-cutting or free-machining stainless steel is developed in this way. The typical material is 303, 416, 303 SE, 430F and other stainless steel.

Element Sulfur exists independently in the form of manganese sulfide and iron sulfide in stainless steel. In the pressure processing, sulfide inclusion elongates along the direction of metal extension, taking the shape of thin strips or spindles, which is equivalent to the formation of countless tiny gaps and damages the continuity of steel. In the cutting and grinding process, the iron chip is easy to break off and fall off, making the machining smooth. Soft sulfide has self-lubricating properties, which can reduce the friction between metal and tool (grinding wheel), improve the service life of tool (grinding), and improve the dimensional accuracy and surface smoothness of the workpiece.

Because the sulfide is distributed in thin strips along the machining direction, the longitudinal tensile strength of free cutting steels decreases very little, but the elongation decreases greatly. Replace sulfur with selenium can significantly improve the ductility of free-cutting steels. The elongation and impact value of selenium free cutting steels are higher than that of sulfur steels, and other mechanical properties are similar. However, selenium is toxic and expensive, so it is seldom used except for important components. Lead – free cutting steels are also rarely used because the lead element is difficult to uniformly disperse in the steel and worker do not want to contact the lead chip.

Free cutting stainless steel is generally delivered with the shape of bar and wire. The surface treatment process of free cutting stainless steel wire is the same as that of other stainless steel wire. After two processes of straightening and non-core grinder polishing, it is usually delivered in the polished state. The drawing plasticity of sulfur free cutting steel wire is slightly worse, and the surface reduction rate per pass (≤25%) and the total surface reduction rate (≤45) during drawing are less than those of similar stainless steel wire. The reserved grinding amount is determined according to the surface quality and size of the steel wire, generally 0.20~0.40mm. The lower limit is taken for the finished steel wire with a diameter of 1.0mm, and the upper limit is taken for the diameter of 8.0mm. According to ASTM 581, the heat treatment temperature of the finished wire in 416 and A condition is controlled between 600~640℃, and the surface reduction rate of the finished wire in 303 and 303Se B condition should be controlled about 24%.

Free cutting stainless steel is generally delivered with the shape of bar and wire. The surface treatment process of free cutting stainless steel wire is the same as that of other stainless steel wire. After two processes of straightening and non-core grinder polishing, it is usually delivered in the polished state. The drawing plasticity of sulfur free cutting steel wire is slightly worse, and the surface reduction rate per pass (≤25%) and the total surface reduction rate (≤45) during drawing are less than those of similar stainless steel wire. The reserved grinding amount is determined according to the surface quality and size of the steel wire, generally 0.20~0.40mm. The lower limit is taken for the finished steel wire with a diameter of 1.0mm, and the upper limit is taken for the diameter of 8.0mm. According to ASTM 581, the heat treatment temperature of the finished wire in 416 and A condition is controlled between 600~640℃, and the surface reduction rate of the finished wire in 303 and 303Se B condition should be controlled about 24%.

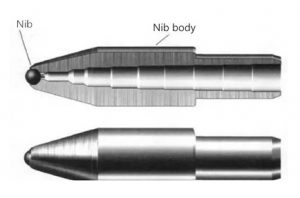

The free-cutting stainless steel wire is mainly used to make the pen tip, especially the ball head and the holder of the ballpoint pen. In addition, it can also be used for manufacturing medical equipment like strings, and facsimile, printer, vending machine, micro motor shaft, refrigerator and other applications.