Sometimes tool steel is referred to as die steel or mould steel, generally referring to the steel used to make cutting tools, gauges, moulds and wear-resistant tools. The tool steel has high hardness, fatigue strength and high-temperature strength, wear resistance and toughness, and its surface can be used directly after precision grinding without additional processing, saving time.

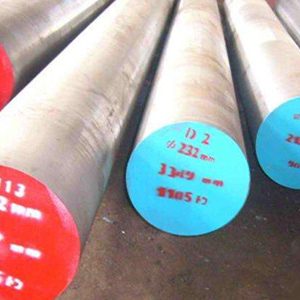

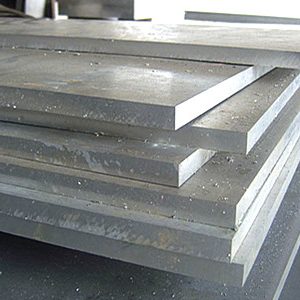

The mechanical parts made by tool steel material offers long service life with extremely high durability. The tool steel WIHO metals are supplying and stocked includes alloy tool steel, high speed steel (HSS), and carbon tool steel. They can be used to make a variety of processing tools, molds and so on. Typical applications include electronic instruments, automobiles, watches, blades, drills, and other mechanical parts that can withstand precision grinding and high impact. Wiho metals stocks and offers high-quality tool steel that is high-cleanliness, good mechanical properties and heat treatment properties in the forms of round bars, flat bars and square, which depend on the diversified needs from customers.

Tool Steel Grades

| Water-hardening tool steel | W grades | W1 Water hardening tool steel |

| Hot-working tool steel | H grades | H11 Hot work tool steel

H13 Hot work tool steel |

| Cold working tool steel | A grades | A2 Air hardening tool steel

A6 Air hardening tool steel A8 Air hardening tool steel A10 Air hardening tool steel |

| D grades | D2 Air hardening tool steel

D7 Air hardening tool Steel |

|

| O grades | O1 Oil hardening tool steel

O6 Oil hardening tool steel |

|

| Shock-resisting tool steel | S grades | S1 Shock resisting tool steel

S5 Shock resisting tool steel S7 Shock resisting tool steel |

| High-speed steel | M grades | M2 High-speed tool steel

M4 High-speed tool steel M42 High-speed tool steel |

| T grades | T1 Air or oil hardening tool

T15 Air or oil hardening tool |