When it comes to gas exhaust structures, you want a material that can both withstand high temperatures and handle the corrosive properties of exhaust fumes. In the old days, galvanized steel pipe or black iron pipe is the common material used for gas exhaust piping and many homeowners and professionals are confused about which pipe is best for their projects. Nowadays, stainless steel might be more popular. In this blog post, we’ll examine the features and benefits of both types of materials to help you decide which one is right for your project. Consideration will include corrosion resistance, temperature considerations, cost comparison and installation methods. Read on to explore the best option for gas exhaust systems!

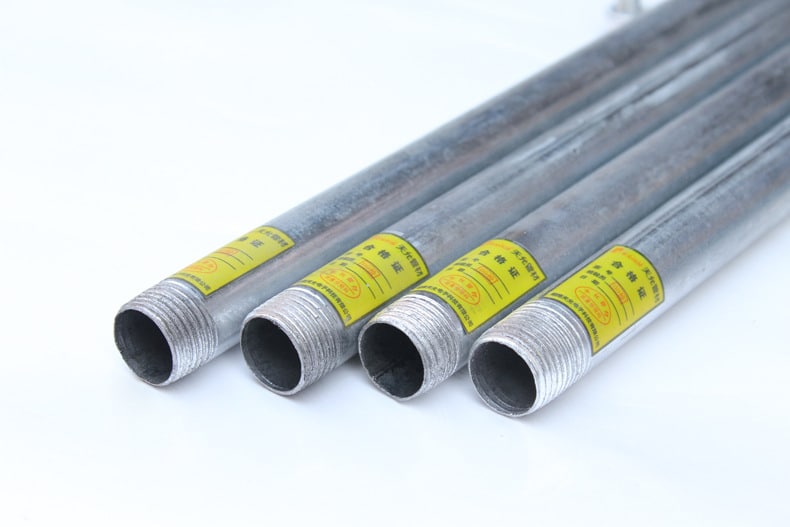

Galvanized steel pipe for gas exhaust is a very durable material that will last a long time. This is because it has a zinc coating that protects it from corrosion. But make sure to avoid soaking it in water or harsh cleaning products for a long time. If you don’t, the galvanized steel will corrode quickly and will eventually become unusable. You may also want to consider hiring a professional for routine maintenance and repairs. This is especially true if your pipes are used outdoors or in areas with moisture.

Stainless steel pipes or SS hollow sections have a long lifespan so you can count on them to hold up over time. Their strength also makes them highly resistant to impacts from outside sources. Due to its impressive durability, stainless steel pipes require minimal maintenance and are usually quite easy to install.

Corrosion Resistance

Galvanized steel pipe is coated with a layer of zinc, making it highly resistant to corrosion. This coating protects the pipes from rusting even if they’re exposed to moisture. It also prevents the buildup of mineral deposits that can clog water lines, which makes it better for outdoor railings, fences, sewage plumbing and farm irrigation because it offers a high level of corrosion resistance. Another benefit of galvanized pipe is that it can withstand high-pressure levels and temperatures, which is important for gas exhaust applications. This makes it an ideal choice for industrial projects. However, it’s important to remember that not all galvanized steel will withstand high temperatures and pressures. If you need to use it for your project, be sure to choose a high-quality product.

You may also want to choose stainless steel or duplex stainless steel, which are more expensive than plain-steel options, but they offer the best corrosion resistance. Common stainless steel pipe is an excellent choice. Its corrosion-resistant properties make it ideal for use in high-temperature environments. This makes it especially suited for both indoor and outdoor applications, as well as areas where strong fumes are present.

Galvanized steel pipe is used to help vent gases from your home, such as carbon monoxide. If you have a galvanized flue pipe in gas furnaces and boilers and it is leaking water, condensation or even gas, it’s best to have it checked out immediately. If you have a furnace that uses a galvanized flue pipe, you need to check it for leaks every year. This is because these leaks can indicate serious problems, such as a carbon monoxide leak or the need for an entirely new furnace. This is important for several reasons. First, a leaking pipe can lead to dangerous carbon monoxide poisoning. Secondly, it can lead to the corrosion of other pipes, including lead pipes. Third, a leaking flue pipe can also indicate the need for an inspection of your entire HVAC system. It’s especially important if you live in an older home and may have lead service lines that have been connected to your home’s plumbing system. Stainless steel pipes, on the other hand, have a long life and generally do not corrode or leak during their service life, meaning it requires little or no maintenance.

Cost

They are saying that the difference in price is the biggest difference between them. Galvanized steel is a popular choice because it’s inexpensive, energy efficient, and durable. Stainless steel pipe is much more expensive than GI steel pipe. Stainless steel won’t corrode and is much easier to work with and is more reliable than their mild steel counterparts. The use of a stainless steel exhaust is also more cost-effective in the long term, as there’s no need to replace galvanized steel pipes over time as a result of wear and tear.

In the last, when considering which type of metal piping to use for your project, you should always consider the unique features and benefits of both galvanized steel pipe and stainless steel pipe. Both materials offer excellent corrosion resistance, temperature considerations, cost comparison and installation methods that are vital to assess before making a decision. However, the best choice depends on the cost and type of flue gas you use. For gas exhaust systems, stainless steel pipes provide superior performance in terms of strength, longevity and maintenance requirements – making them the best choice for many applications. High-temperature flue gas typically requires galvanized steel, while lower-temperature flue gas is better suited for stainless steel or PVC.