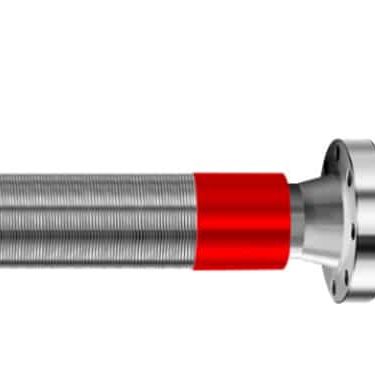

Hydraulic Hose

- Type: Steel wire spiral, steel wire braid

- Standards: SAE, DIN, ISO, GB, MSHA, MT, etc.,

- Temperature range:-40°C – +121°C (-40oF〜+250°F) ;-55°C 〜+100°C (-67°F~ +212°F)

As leading hydraulic hose manufacturer, Wiho Industrial offers a range of oil hoses that can deliver high performance and can withstand the harshest working environments. Our hydraulic hoses are designed for medium or low pressure and hydraulic service, suitable for a variety of harsh applications. Wiho Industrial offers a full line of standard and specialty hydraulic hoses with both braided and spiral construction that meet SAE standards, we also have hoses and many specialty hydraulic hoses to meet specific applications. Including:

Types We Can Do

Standards: ISO1436:2009 ISO1817:2005 ISO8330:1998 ISO6605:2002

Applications: For the delivery of hydraulic liquids or water braid liquids.

Constructions: Made of excellent oil-resistant and anti-aging rubber. The reinforcement is copper-clad steel wire The cover is available in black color with a wrapped surface. The hose is made in conformity with the DIN EN853 1SN standard and SAE J517 100R1AT standard. The working temperature range is -40℃~ +100℃ (-40 ℉~ +212 ℉ ).

Specifications

|

Size |

I.D. |

W.D. |

O.D. | T.H |

Max.W.P |

P.P |

Min.P.P |

Min.B.R |

W.T |

||||

| MIN | MAX | MIN | MAX | MAX | MIN | MAX | |||||||

| DASH | IN | mm | mm | mm | mm | mm | mm | mm | MPa | MPa | MPa | mm | Kg/m |

| -3 | 3/16 | 4.6 | 5.4 | 9.0 | 10.0 | 12.5 | 0.8 | 1.5 | 25.0 | 50.0 | 100.0 | 90 | 0.20 |

| -4 | 1/4 | 6.2 | 7.0 | 10.6 | 11.6 | 14.1 | 0.8 | 1.5 | 22.5 | 45.0 | 90.0 | 100 | 0.23 |

| -5 | 5/16 | 7.7 | 8.5 | 12.1 | 13.3 | 15.7 | 0.8 | 1.5 | 21.5 | 43.0 | 85.0 | 115 | 0.28 |

| -6 | 3/8 | 9.3 | 10.1 | 14.5 | 15.7 | 18.1 | 0.8 | 1.5 | 18.0 | 36.0 | 72.0 | 130 | 0.33 |

| -8 | 1/2 | 12.3 | 13.5 | 17.5 | 19.0 | 21.4 | 0.8 | 1.5 | 16.0 | 32.0 | 64.0 | 180 | 0.40 |

| -10 | 5/8 | 15.5 | 16.7 | 20.6 | 22.2 | 24.5 | 0.8 | 1.5 | 13.0 | 26.0 | 52.0 | 200 | 0.48 |

| -12 | 3/4 | 18.6 | 19.8 | 24.6 | 26.2 | 28.5 | 0.8 | 1.5 | 10.5 | 21.0 | 42.0 | 240 | 0.62 |

| -16 | 1 | 25.0 | 26.4 | 32.5 | 34.1 | 36.6 | 0.8 | 1.5 | 8.8 | 17.5 | 35.0 | 300 | 0.91 |

| -20 | 1 1/4 | 31.4 | 33.0 | 39.3 | 41.7 | 44.8 | 1.0 | 2.0 | 6.3 | 13.0 | 25.0 | 420 | 1.18 |

| -24 | 1 1/2 | 37.7 | 39.3 | 45.6 | 48.0 | 52.1 | 1.3 | 2.5 | 5.0 | 10.0 | 20.0 | 500 | 1.42 |

| -32 | 2 | 50.4 | 52.0 | 58.7 | 61.7 | 65.5 | 1.3 | 2.5 | 4.0 | 8.0 | 16.0 | 630 | 1.90 |

Standards: ISO1436:2009 ISO1817:2005 ISO8330:1998 ISO6605:2002

Applications: For the delivery of hydraulic liquids or water liquids.

CONSTRUCTION: Made of excellent oil-resistant and anti-aging rubber. The reinforcement is copper-clad steel wire The cover is available in black color with the wrapped surface. The hose is made in conformity with DIN EN853 2SN standard and SAE J517 100R2AT standard. Working temperature range is -40℃~ +100℃ (-40 ℉~ +212 ℉ ).

Specifications

|

Size |

I.D. | W.D. | O.D. | Thickness |

Max.W.P |

P.P |

Min.P.P |

Min.B.R |

Weight |

||||

| MIN | MAX | MIN | MAX | MAX | MIN | MAX | |||||||

| DASH | IN | mm | mm | mm | mm | mm | mm | mm | MPa | MPa | MPa | mm | Kg/m |

| -3 | 3/16 | 4.6 | 5.4 | 10.6 | 11.6 | 14.1 | 0.8 | 1.5 | 41.5 | 83.0 | 166.0 | 90 | 0.32 |

| -4 | 1/4 | 6.2 | 7.0 | 12.1 | 13.3 | 15.7 | 0.8 | 1.5 | 40.0 | 80.0 | 160.0 | 100 | 0.35 |

| -5 | 5/16 | 7.7 | 8.5 | 13.7 | 14.9 | 17.3 | 0.8 | 1.5 | 35.0 | 70.0 | 140.0 | 115 | 0.41 |

| -6 | 3/8 | 9.3 | 10.1 | 16.1 | 17.3 | 19.7 | 0.8 | 1.5 | 33.0 | 66.0 | 132.0 | 130 | 0.50 |

| -8 | 1/2 | 12.3 | 13.5 | 19.0 | 20.6 | 23.0 | 0.8 | 1.5 | 27.5 | 55.0 | 110.0 | 180 | 0.62 |

| -10 | 5/8 | 15.5 | 16.7 | 22.2 | 23.8 | 26.2 | 0.8 | 1.5 | 25.0 | 50.0 | 100.0 | 200 | 0.72 |

| -12 | 3/4 | 18.6 | 19.8 | 26.2 | 27.8 | 30.1 | 0.8 | 1.5 | 21.5 | 43.0 | 85.0 | 240 | 0.92 |

| -16 | 1 | 25.0 | 26.4 | 34.1 | 35.7 | 38.9 | 0.8 | 1.5 | 16.5 | 32.5 | 65.0 | 300 | 1.30 |

| -20 | 1 1/4 | 31.4 | 33.0 | 43.3 | 45.7 | 49.5 | 1.0 | 2.0 | 12.5 | 25.0 | 50.0 | 420 | 1.80 |

| -24 | 1 1/2 | 37.7 | 39.3 | 49.6 | 52.0 | 55.9 | 1.3 | 2.5 | 9.0 | 18.0 | 36.0 | 500 | 2.20 |

| -32 | 2 | 50.4 | 52.0 | 62.3 | 64.7 | 68.6 | 1.3 | 2.5 | 8.0 | 16.0 | 32.0 | 630 | 3.00 |

This hose shall consist of an inner tube of oil-resistant synthetic rubber, multiple spiral plies of steel wire wrapped in alternating directions and an oil and weather resistant synthetic rubber cover. The hose is made in conformity with SAE 100R13 and GB/T 10544-2013 standards. This section covers the hose for use with petroleum base hydraulic fluids within a temperature range of -40° C +121° C(-40° F +250° F).

Specifications

| Size | I.D. | W.D. | O.D. | Max.W.P |

P.P |

Min.P.P |

Min.B.R |

Weight |

||||

| MIN | MAX | MIN | MAX | MIN | MAX | |||||||

| DASH | IN | mm | mm | mm | mm | mm | mm | MPa | MPa | MPa | mm | Kg/m |

| -12 | 3/4 | 18.6 | 19.8 | 28.2 | 29.8 | 31.0 | 33.2 | 35 | 70 | 140 | 240 | 1.50 |

| -16 | 1 | 25.0 | 26.4 | 34.9 | 36.4 | 37.6 | 39.8 | 35 | 70 | 140 | 300 | 2.00 |

| -20 | 1 1/4 | 31.4 | 33.0 | 45.6 | 48.0 | 48.3 | 51.3 | 35 | 70 | 140 | 420 | 3.80 |

| -24 | 1 1/2 | 37.7 | 39.3 | 53.1 | 55.5 | 55.8 | 58.8 | 35 | 70 | 140 | 500 | 4.50 |

| -32 | 2 | 50.4 | 52.0 | 66.9 | 69.3 | 69.5 | 72.7 | 35 | 70 | 140 | 640 | 6.50 |

This hose shall consist of an inner tube of oil-resistant synthetic rubber, multiple spiral-resistant synthetic rubber covers. This section covers the hose for use with petroleum base hydraulic fluids within a temperature range of -40° C +121° C(-40° F +250° F).

Specifications

|

Size |

I.D. | W.D. | O.D. | Max.W.P | P.P | Min.P.P | Min.B.R | Weight | ||

| MIN | MAX | MIN | MAX | |||||||

| DASH | IN | mm | mm | mm | mm | MPa | MPa | MPa | mm | Kg/m |

| -6 | 3/8 | 9.3 | 10.1 | 20.3 | 23.3 | 42 | 84 | 168 | 150 | 0.75 |

| -8 | 1/2 | 12.3 | 13.5 | 24.0 | 26.8 | 42 | 84 | 168 | 200 | 0.90 |

| -12 | 3/4 | 18.6 | 19.8 | 32.9 | 36.1 | 42 | 84 | 168 | 265 | 1.40 |

| -16 | 1 | 25.0 | 26.4 | 38.9 | 42.9 | 42 | 84 | 168 | 330 | 2.10 |

| -20 | 1 1/4 | 31.4 | 33.0 | 48.4 | 51.5 | 42 | 84 | 168 | 445 | 3.90 |

| -24 | 1 1/2 | 37.7 | 39.3 | 56.3 | 59.6 | 42 | 84 | 168 | 530 | 4.65 |

This hose shall consist of an inner tube of oil-resistant synthetic rubber, four plies of steel wire wrapped in alternating directions and an oil and weather-resistant synthetic rubber cover. The hose is made in conformity with EN856-4SP and/T 10544-2013 standards. This section covers hose for use with petroleum base hydraulic fluids within a temperature range of -40° C +100° C(-40° F +212° F).

Specifications

|

Size |

I.D. | W.D. | O.D. |

Max.W.P |

P.P |

Min.P.P |

Min.B.R |

W.T |

||||

|

MIN |

MAX |

MIN |

MAX |

MIN |

MAX |

|||||||

| DASH | IN | mm | mm | mm | mm | mm | mm | MPa | MPa | MPa | mm | Kg/m |

| -4 | 1/4 | 6.2 | 7.0 | 14.1 | 15.3 | 17.1 | 18.7 | 45 | 90 | 180 | 150 | 0.64 |

| -6 | 3/8 | 9.3 | 10.1 | 16.9 | 18.1 | 20.6 | 22.2 | 44.5 | 89 | 178 | 180 | 0.75 |

| -8 | 1/2 | 12.3 | 13.5 | 19.4 | 21.0 | 23.8 | 25.4 | 41.5 | 83 | 166 | 230 | 0.90 |

| -10 | 5/8 | 15.5 | 16.7 | 23.0 | 24.6 | 27.4 | 29.0 | 35 | 70 | 140 | 250 | 1.10 |

| -12 | 3/4 | 18.6 | 19.8 | 27.4 | 29.0 | 31.4 | 33.0 | 35 | 70 | 140 | 300 | 1.44 |

| -16 | 1 | 25.0 | 26.4 | 34.5 | 36.1 | 38.5 | 40.9 | 28 | 56 | 112 | 340 | 1.98 |

| -20 | 1 1/4 | 31.4 | 33.0 | 45.0 | 47.0 | 49.2 | 52.4 | 21 | 42 | 84 | 460 | 2.85 |

| -24 | 1 1/2 | 37.7 | 39.3 | 51.4 | 53.4 | 55.6 | 58.8 | 18.5 | 37 | 74 | 560 | 3.35 |

| -32 | 2 | 50.4 | 52.0 | 64.3 | 66.3 | 68.2 | 71.4 | 16.5 | 33 | 66 | 660 | 5.40 |

This hose shall consist of an inner tube of oil-resistant synthetic rubber, four plies of steel wire wrapped in alternating directions and an oil and weather-resistant synthetic rubber cover. The hose is made in conformity with EN856-4SH and/T 10544-2013 standards. This section covers hose for use with petroleum base hydraulic fluids within a temperature range of -40° C +100° C(-40° F +212° F).

| Size | I.D. | W.D. | O.D. |

Max.W.P |

P.P |

Min.P.P |

Min.B.R |

Weight |

||||

| MIN | MAX | MIN | MAX | MIN | MAX | |||||||

| DASH | IN | mm | mm | mm | mm | mm | mm | MPa | MPa | MPa | mm | Kg/m |

| -10 | 5/8 | 15.5 | 16.7 | 23.2 | 24.8 | 27.4 | 29.0 | 45 | 90 | 180 | 250 | 1.10 |

| -12 | 3/4 | 18.6 | 19.8 | 27.6 | 29.2 | 31.4 | 33.0 | 42 | 84 | 168 | 280 | 1.40 |

| -16 | 1 | 25.0 | 26.4 | 34.4 | 36.0 | 37.5 | 39.9 | 38 | 76 | 152 | 340 | 2.00 |

| -20 | 1 1/4 | 31.4 | 33.0 | 40.9 | 42.9 | 43.9 | 47.1 | 32.5 | 65 | 130 | 460 | 2.55 |

| -24 | 1 1/2 | 37.7 | 39.3 | 47.8 | 49.8 | 51.9 | 55.1 | 29 | 58 | 116 | 560 | 3.05 |

| -32 | 2 | 50.4 | 52.0 | 62.2 | 64.2 | 66.5 | 69.7 | 25 | 50180 | 100 | 700 | 4.35 |