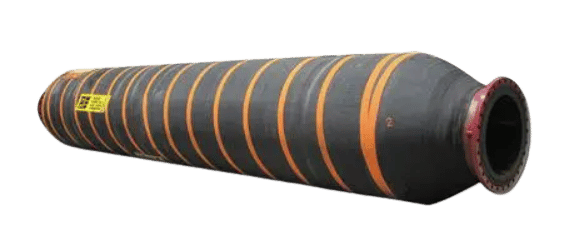

Double Carcass Floating Hose

- Type: Floating

- Internal diameter: 6” to 24”

- Design pressure: 15, 19 and 21 bar

- Inner lining material: Nitrile, HNBR and Viton

- Length(Max.): Up to 12.2 m

- Applications: Crude oil and oil production

Carcass Floating Hoses are a reliable and durable solution for exposed offshore installations. A marine hose can be a single-carcass or double-type. Double Carcass Hoses are flexible hose which has two carcasses that are made of textile-reinforced bonded elastomers and designed so that if the main carcass fails, The first carcass serves as a conduit for the fluid to be conveyed and the secondary carcass contains space for fluid retention and protects the ambient environment. The double carcass hose can handle higher flow rates compared with a single carcass hose.

Double carcass hoses are an important safety component for marine applications used in the transport of crude oil fluids that can be polluted the environment. These hoses have the ability to contain a leak if it occurs because they can be designed to include an alert device in case of failure. WIHO industrial is a manufacturer and supplier of Single Carcass Hose comply with GMPHOM and is manufactured under ISO certification. The hose we provide is made of multiple plies of high-performance steel and rubber materials suitable for work in extremely rough conditions in long-lasting applications. The double carcass hoses supplied by WIHO Industrial are made from some materials and are designed with various features to meet specific needs.

Gerneral Speficicaions

| Size | 150 mm (6”), 200 mm (8”), 250 mm (10”), 300 mm (12”), 400 mm (16”), 500 mm (20”), 600 mm (24”) |

| Length | 9.1M (30”), 10.7M (35”) & 12.2M (40”)(non-standard less than 12.2M also available) |

| Hose Construction | Liner Tube: NBR-based Rubber, resistant to hydrocarbons with aromatic content up to 60%.

Main carcass: Elastomer reinforced with multi-layers of high tensile textile cords and embedded steel with helix. |

| Pressure Rating | Primary Carcass -15 bar, 19 bar, 21 bar (higher pressure ratings on request)

Secondary Carcass -15 bar, 19 bar, 21 bar. |

| Minimum Burst Pressure | Primary Carcass – 75 bar, 95 bar, 105 bar

Secondary Carcass – 30 bar, 38 bar, 42 bar. |

| Flow Velocity | Maximum of 21m/s |

| Temperature Range | Fluid Temperature from -20 o C to 82 o C.

Ambient Temperature from-29 o C to 52 o C. |

| Minimum Bend Radius | Submarine Hose-4 x hose Nominal Bore Diameter. Floating Hose – 6 x hose Nominal Bore Diameter |

| Electrical Continuity | Electrically Continuous or Discontinuous as required. |

| Leak Detection | Pressure compensated leak detection system for Floating, Submarine applications. |

Types We Can Do

Customized Type:

- 52110 End reinforced half floating hose

- 52120 Controlled buoyancy floating hose

- 52130 Main line floating hose

- 52140 Mainline half floating hose

- 52150 Reduced floating hose

- 52160 Tail floating hose

- 52170 Tanker rail floating hose

- 52180 End reinforced high buoyancy floating(First off FPSO to support ERC) hose

- 52190 ST END reinforced high buoyancy floating(Shuttle tanker connection to support HEV) hose