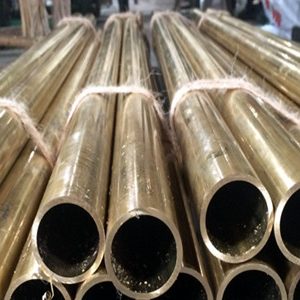

C70600 Copper-Nickel Tubing

Specifications:ASTM B111, B466

Size: 16mm-419mm

Length: 6000mm

Forms: Round Tubing

Temper: H55

Copper-nickel (also known as cupronickel) alloys offer excellent corrosion resistance to seawater and good fabricability. The addition of nickel to copper improves strength and corrosion resistance while allowing the alloy to remain ductile, other elements can be added to copper-nickel to increase strength, corrosion resistance, hardening, weldability and castability. The nickel-copper alloy has been widely used for r marine applications. C70600 often known as 90-10 copper-nickel, is the alloy with 90% copper and 10% nickel, has been widely used in the automotive, admiralty, shipping, offshore as well as power generation.

Wiho metals is a fully stocked and leading metal manufacturer, supplier, exporters, distributors. We stock the copper alloy mill-product in the forms of plate, tubing, bar and rod. The copper alloy products provide by us shall be fabricated from prime quality raw materials and is fully certifiable to industrial specifications like ASTM and ASME or other relevant standards. Wiho metals supply and stock a large inventory of alloy Copper C70600 (C706/CW352H/C7060T) tubing in accordance with ASTM B111, B466 used for condensers, heat exchanger, the power steering tube, brake Lines applications. For more information on our extensive copper alloys inventory, please contact us or fill in the form below.

C70600 Equivalent Material

| Type | ASTM | EN | BS | DIN | JIS | GB |

| 90Cu-10Ni | C70600 | CW352H | CN102 | CuNi10Fe 1Mn

CuNi10Fe 1.6Mn |

C7060T | B10(BFe30-1-1) |

C70600 Tubing Specifications

| C70600 Seamless Pipe | ASTM B466, ASME SB466, ASTM B111, ASME SB111,ASTM B552 |

| C70600 Welded Pipe | ASTM B608, B467, ASME SB467, ASTM B552 |

C70600 Tube Chemical Composition

| CU | Fe | Ni+Co | Pb | Sn | Mn | Zn |

| 88.600 | 1.0 – 1.5 | 9.0 – 11.0 | ≤0.05 | ≤0.03 | 0.5~1.0 | ≤0.3 |

C70600 Tube Mechanical Property

| Temper code | Tensile strength, Mpa | Yield strength, Mpa | Elongation, % |

| H55 | 414 | 393 | 10 |

C70600 Tube Physical Properties

| Density | 8.94 gm/cm3 @ 20 C |

| Melting Point – Liquidus | 1149 C |

| Electrical Conductivity | 0.053 MegaSiemens/cm @ 20 C |

| Coefficient of Thermal Expansion | 17.1 . 10-6 per oC (20-300 C) |