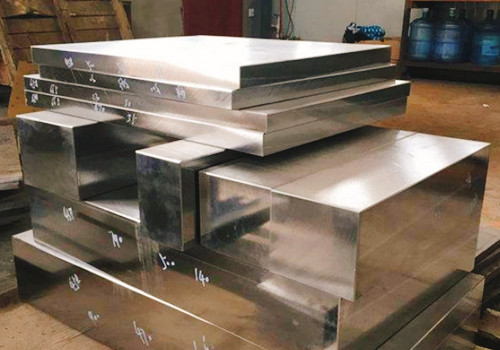

Carbon tool steel VS Carbon mold steel

Some people often confused tool steels with mold steels because their definitions seem similar. Generalized tool steels include mold steels, which have some common characteristics, such as the need to bear great local pressure and strong wear, how to achieve the balance of toughness and wear resistance is their biggest contradiction. In a narrow sense,…