Chromoly steel 4130 has excellent strength and toughness, good hardenability and weldability, is a commonly used steel pipe for structural and mechanical purposes. It is mainly used for quenching and tempering parts with large cross-sections and working under high-stress conditions in the machinery manufacturing industry such as shafts, spindles, high load steering wheels, bolts, studs, gears, etc. For the chemical industry, it can be used to manufacture welding parts, or high-pressure conduit in the nitrogen and hydrogen medium working temperature less than 250℃; or manufacture fasteners below 450℃ in steam turbine and boiler manufacturing industry. As we know, 4130 steel pipe is widely used in such racing car frames, roll cages, sand cars, bicycle and motorcycle frames, etc. The roll cage frame can withstand a variety of loads from inside and outside the car where need good strength and weldability. Today we will introduce a design of the 4130 bending roll cage frame.

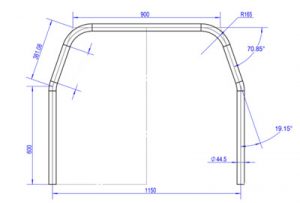

4130 steel bend technical specification(mm)

Both sides of the elbow radius should be the actual radius and be the same;

Both sides of the elbow radius should be the actual radius and be the same;- The size of the elbow shall be marked according to the centerline of the steel pipe, including the length between the intersection points of the branch pipes on both sides, and the outer Angle of the elbow (at least one decimal);

- The minimum distance between the two bends should not be less than 4 times the diameter of the steel pipe to ensure that the continuous bending can be normally installed.

You can also process space tube elbow by increasing the rotation Angle to meet the requirements above.

| Steel pipe diameter | The theory radius | The actual radius | Minimum straight segment |

| 15.90 | 60 | 62 | 70 |

| 19.05 | 60 | 62 | 70 |

| 22.30 | 60 | 62 | 75 |

| 25.40 | 76.5 | 79 | 105 |

| 31.75 | 101 | 105 | 120 |

| 38.10 | 127 | 132 | 135 |

| 44.45 | 152 | 160 | 150 |

Pipe bending size tolerance

Dimension tolerance: Spacing of adjacent branches is ±3mm, U-shaped spacing is ±1%.

Angle tolerance: ± 0.3 degrees.

There is a deviation between the actual elbow radius and the theoretical radius. In the production of structures such as roll cage frames, the deviation of the groove calculated by the theoretical radius will be large, so the adjustment should be made and the actual radius should be directly used in the design. The rules of the FIA race have clear provisions on the bending processing of the main steel pipe of the roll cage frame. The tubing must be bent by a cold working process and the centreline bend radius must be at least 3 times the tube diameter.

Size test

The Angle of the elbow is generally measured with a digital Angle ruler, spacing by a tape measure and auxiliary tools. We can also scan the three-dimensional point cloud of the elbow with higher size requirements, and compare the overall size with the original digital model in the computer software.

WIHO metals is a professional supplier and inventory supplier of chromium-molybdenum steel pipes. We provide design and processing services of ASTM A519 4130 and 4140 steel pipes. When the steel pipes are in stock, we guarantee that most of the bending pipes can be delivered within 7 days. Large quantities and special specifications of the elbow processing time needs to be customized according to the drawings.