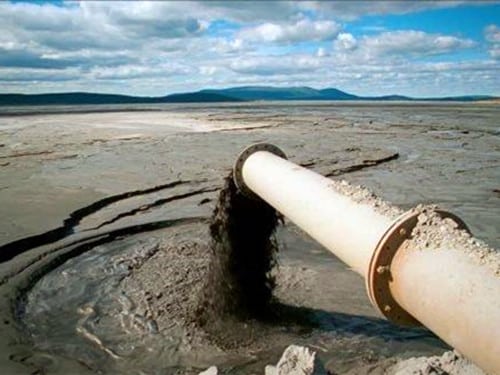

The urban sewage system is like the veins of the human body to maintain public health and environmental sustainability. As integral components of a city’s infrastructure, sewage pipe lines ensure the proper disposal of wastewater and sewage. Common materials used for these pipes include polyvinyl chloride (PVC), fiberglass, cast iron, reinforced concrete and so on. The selection of different materials should be based on the needs of specific projects, strength of the material, corrosion resistance, maintenance, and future solutions related to sewage pipe lines is vital for efficient urban living.

ASTM A252: This standard covers steel pipe piles, which can also be used in sewage pipelines due to their structural strength and suitability for large-diameter applications.

ASTM A139: This specification pertains to electric-fusion (arc)-welded steel pipe sizes that are suitable for use in conveying gas, water, and sewage. It includes grades A, B, and C, each with varying strengths and wall thicknesses.

ASTM A53: This standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded and seamless steel pipe. ASTM A53 Grade B steel pipes are suitable for use in conveying gas, water, and sewage with varying strengths and wall thicknesses.

API 5L: This specification outlines steel pipe requirements for conveying gas, water, and oil in both the natural gas and petroleum industries. Some grades within API 5L, such as X52 or X56, might be utilized for large-diameter sewage pipelines due to their strength and corrosion resistance.

EN 10219: This European standard covers technical delivery conditions for welded steel pipes used in various applications, including sewage systems, with specific grades meeting structural requirements.

The choice of grade and specifications for steel pipes in large-diameter sewage pipelines depends on factors like the environment, soil conditions, required strength, corrosion resistance, and regulatory standards in the region where the pipeline is installed. It’s crucial to consult engineering and industry standards to select the most suitable steel pipe grade and specifications for a particular sewage system project.

Advantages and Disadvantages of Steel Sewage Pipelines

When choosing materials for sewer lines and drain pipes in construction, various factors need to be considered. Metal sewage pipelines, typically made of materials like cast iron or carbon steel, have their own set of advantages and disadvantages when compared to other materials such as PVC (polyvinyl chloride) or concrete.

|

Advantages |

Disadvantages |

| Durability;

Fire resistance; Good resistance to corrosion; Longer lifespan; High-temperature resistance; Structural integrity, suitable for areas with significant traffic or construction activity; |

More expensive; higher installation costs; Heavier than PVC pipe; Will corrode in environments conveying certain aggressive chemicals or with aggressive soils or high levels of acidity; |

While steel pipes can be an option, the selection of materials for sewage pipelines often considers various aspects like type of sewage, environmental conditions, cost, longevity, maintenance requirements, the overall infrastructure design, and compatibility with the sewage system. WIHO Industrial will provide you with sewer pipes that have been lined and coated for sewer applications. Steel Sewer pipeline at WIHO is available in ASTM A139, ASTM A53, as well as galvanized and epoxy lined and coated service.