Stainless steel pipes are versatile components used in various industries, from construction to manufacturing. We all know that stainless steel bends are actually made of straight pipes, and this way of changing from a bend to a straight pipe is bending processing. Sometimes, the need arises to bend these pipes to fit specific designs or configurations. However, its unique characteristics make it both durable and challenging to process. Therefore, bending stainless steel pipes requires careful consideration of their properties and the appropriate bending methods. In this guide, we’ll walk you through the process of bending stainless steel pipes grade 304 effectively and safely. Whether you’re a DIY enthusiast or a professional, these steps will help you achieve the desired results.

Types of Bending Methods

Stainless steel Grade 304 is known for its resistance to corrosion, heat, and wear. It’s important to note that while stainless steel is resilient, certain factors such as wall thickness, alloy composition, and temper can affect its bendability. This is why choosing the right bending method is crucial.

Cold Bending

Cold bending is a common method used for moderate bends. It involves using a pipe bender to shape the pipe without applying heat. This method is suitable for pipes with thinner walls. During processing, the friction between the stainless steel tube and the tool will produce high heat, making the tool easy to wear, requiring the tool material to wear and resist high temperature. In addition, the heat generated during the processing process is large, and it is recommended to use sulfur chloride cooling oil, which has a better effect. The most difficult is to drill deep holes and tap, which puts higher demands on workers who process stainless steel round pipes

Cold bending is a common method used for moderate bends. It involves using a pipe bender to shape the pipe without applying heat. This method is suitable for pipes with thinner walls. During processing, the friction between the stainless steel tube and the tool will produce high heat, making the tool easy to wear, requiring the tool material to wear and resist high temperature. In addition, the heat generated during the processing process is large, and it is recommended to use sulfur chloride cooling oil, which has a better effect. The most difficult is to drill deep holes and tap, which puts higher demands on workers who process stainless steel round pipes

Guide to Cold Bending

- Tools and equipment: Pipe bender

- Marking and Measuring. Begin by measuring and marking the exact point where you want the bend to start and end. Use a marker to clearly indicate these points on the pipe.

- Securing the Pipe. Place the stainless steel pipe securely in the pipe bender, aligning the marked points with the bending marks on the bender.

- Using a Pipe Bender. Gently pull down the handle of the pipe bender to bend the pipe. Apply steady and even pressure to achieve a smooth bend. Check the angle with a protractor as you bend.

Hot Bending

Hot bending involves heating the stainless steel pipe to a specific temperature before bending. This method is ideal for larger and thicker pipes, as it reduces the risk of cracking or wrinkling.

Guide to Hot Bending

- Tools and equipment: Heating equipment

- Preheating the Pipe. Use a heating torch to evenly heat the section of the stainless steel pipe that needs to be bent. Make sure to heat it until it’s malleable but not red-hot.

- Bending Process. Once the pipe is adequately heated, use a bending tool or jig to carefully bend the pipe to the desired angle. Apply gradual pressure to avoid deformities.

- Cooling and Annealing. After bending, allow the pipe to cool slowly to room temperature. To eliminate stress and restore the stainless steel’s properties, perform an annealing process.

Induction Bending

Induction bending utilizes an induction coil to heat a specific area of the pipe, allowing for precise bends. This method is often used for complex designs and tight radius bends.

Guide to Induction Bending

- Tools and equipment: Induction bending machine

- Induction Heating. Position the induction coil around the section of the pipe you intend to bend. Apply heat using the induction machine until the pipe reaches the desired temperature.

- Bending with Precision. Gently manipulate the pipe to achieve the desired bend. The precise control offered by induction bending makes it suitable for intricate designs.

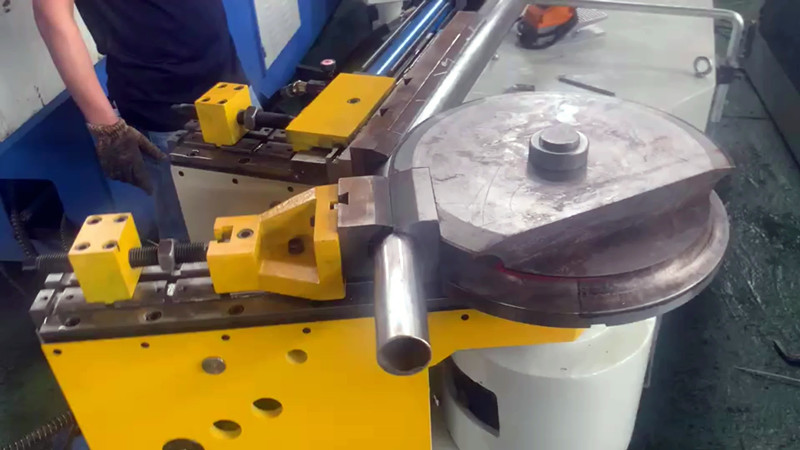

Rotary Draw Bending

Rotary draw bending employs a die set and a counter-bending die to achieve accurate and consistent bends. This method is commonly used in manufacturing and automotive industries.

Guide to Rotary Draw Bending

- Tools and equipment: Rotary draw bending machine

- Machine Setup. Select the appropriate die set and counter-bending die for the desired bend. Secure the pipe in the machine and adjust the settings according to the pipe’s specifications.

- Bending Execution. Activate the machine to initiate the bending process. The die set and counter-bending die work together to create a consistent and accurate bend.

Tips for Achieving Accurate Bends

- Proper Measuring Techniques: Accurate measurements ensure precise bends that fit your project’s specifications.

- Avoid Overheating the Pipe: Excessive heat can weaken the stainless steel, leading to cracks or deformities.

- Using a Mandrel: Placing a mandrel inside the pipe prevents collapsing and wrinkling during the bending process.Inaccurate measurements or poor technique can lead to bends that do not meet your requirements.

- Lubrication: Applying lubricant on the pipe’s exterior reduces friction and eases the bending process.

Post-Bending Processes

After bending the stainless steel pipe, consider these post-bending steps:

- Removing Wrinkles: Smooth out any wrinkles or imperfections on the bent section using appropriate tools.

- Ensuring Structural Integrity: Inspect the bend for any cracks or deformities that may affect its structural integrity.

Remember, safety should be your top priority when bending stainless steel pipes. Ensure you’re wearing appropriate protective gear and working in a well-ventilated area. Additionally, secure the pipe properly to prevent accidents during bending.