Both Electrolytic copper and Oxygen-free copper are pure copper. They can be made into copper wires, bars, plates, or sheets for the electronics industry, and their appearance looks the same, showing purplish-red color. Are they different?

Firstly, let’s explain what’s electrolytic copper. A thick plate of crude copper (containing 99% copper) was made in advance as the anode, and a thin sheet of pure copper was made as the cathode, which was immersed in an electrolytic copper refining tank containing mixed electrolyte of sulfuric acid (H2SO4) and copper sulfate (CuSO4). After electricity, copper dissolves into copper ions (Cu) from the anode and moves to the cathode. After reaching the cathode, electrons are obtained and pure copper is precipitated at the cathode. Impurities such as iron and zinc, which are more active than copper, dissolve together with copper into ions (Zn and Fe). As these ions are not easy to precipitate compared with copper alloys, so as long as the potential difference is properly adjusted during electrolysis can avoid these ions precipitate on the anode. Impurities less active than copper, such as gold and silver, are deposited at the bottom of the cell. Generally, the value of the sludge is enough to cover the costs of the large amounts of electricity required to run the electrolytic refining process. In addition, the anode slime has a high economic value when it is recycled. When they are reprocessed, they are rich in gold and silver, which are then recovered. The copper produced by this process is called “electrolytic copper” and can be consumed to make electrical products.

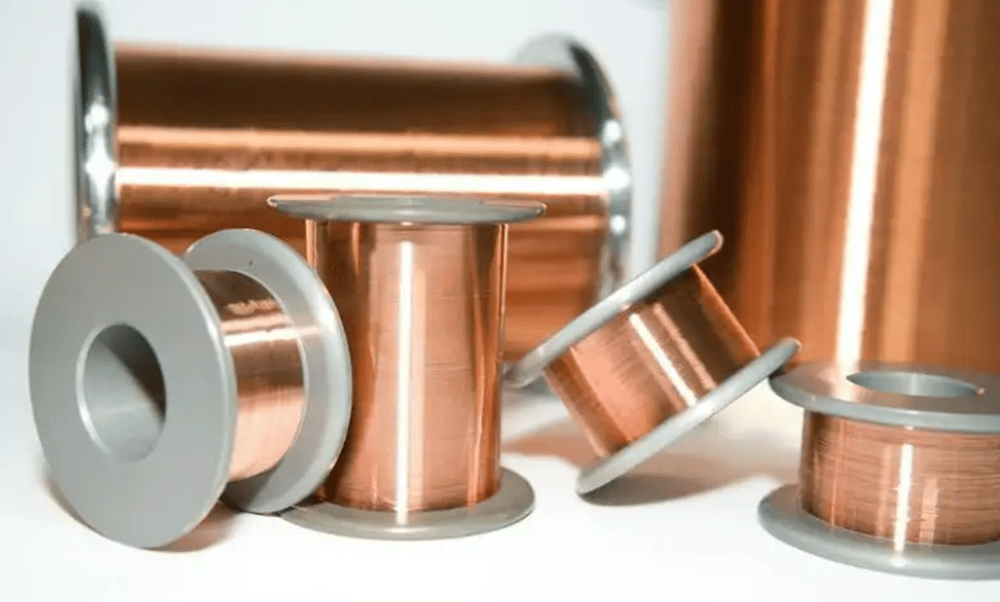

- Electrical industry: cable and wire, motor and transformer winding resistance, switches and printed circuit boards, etc.

- Light industry: air conditioner and refrigerator heat exchanger copper tube;

- Machinery manufacturing industry: industrial valves and accessories, instruments, sliding bearings, molds, heat exchangers and pumps, etc.

- Construction industry: pipeline, pipeline fittings, decorative devices, etc.

- National defense industry: manufacture bullets, shells, gun parts, etc.

The use of electrolytic copper is far more than that, it has great demand in the chemical industry, handicraft manufacturing, energy, petrochemical and so on.

Oxygen-free Copper

The oxygen-free copper has excellent conductivity and long service life. It also has the advantage of minimal voids and crack-free bends. Oxygen-free copper is used extensively in the electrical & electronics industry for current transmission and winding applications. The wires are used in a variety of applications including heavy industrial equipment, consumer electronics, and winding applications. some of the scientific applications include constructing superconductors, electromagnets, magnetometers, and vacuum interrupters. It is widely used in the automotive industry, medical sector as well as in aerospace applications. In addition, it serves as an excellent material for manufacturing anodes.

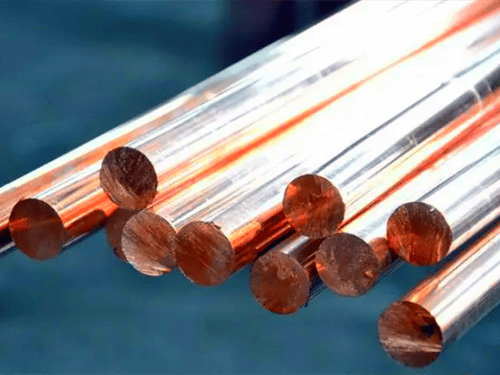

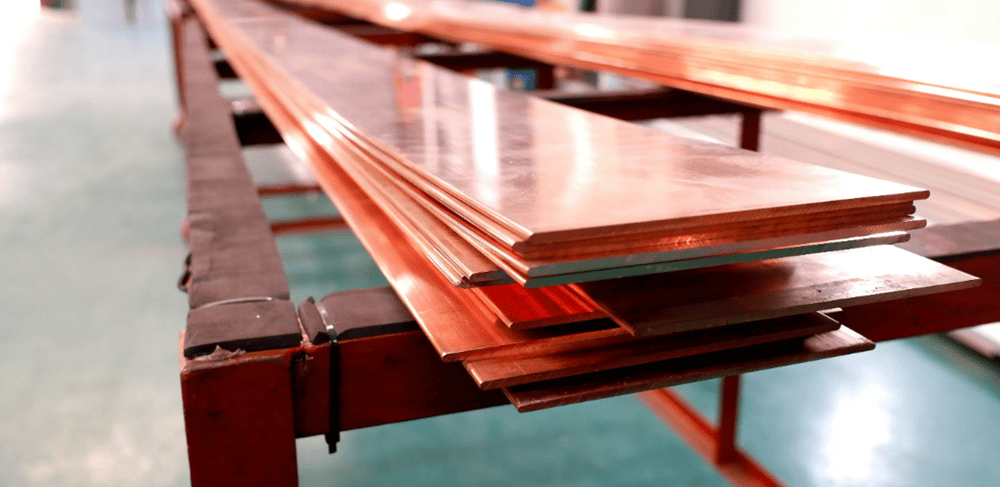

Electrolytic Copper and oxygen-free copper can be made into wire rods, wires, plates and billets, they also can be used to make high-quality copper alloy products used in a wide range of electrical applications. The difference is their applications and electrolytic copper is a very important raw material in the wire and cable industry.